이번에 사파이어 플러스 v3를 직구로 구매하게 되었다.

기본 큐브 파일에 만족하곤, 라즈베리파이5로 Klipper를 구동하는 중이다.

참고로, 라즈베리파이에 Klipper를 설치할려고 한다면 왠만하면

KIAUH를 사용하기를 추천한다.

GitHub - dw-0/kiauh: Klipper Installation And Update Helper

Klipper Installation And Update Helper. Contribute to dw-0/kiauh development by creating an account on GitHub.

github.com

(라즈베리파이5는 공식 OctoPi (Octoprint가 탑재된 기본 OS)버전이 없어,

설치 하는데만 해도 하루정도 꽤 애를 먹었다.)

본론으로 들어가, 사파이어 플러스의 printer.cfg를 아래에 작성해 놓겠다. 파일도 있으니

참고하길 바란다. 해외 레딧유저들과 국내 블로거 (굿맨)의 printer.cfg를 참고했다.

*보드: MKS robin nano v3.1

UI: Mainsail

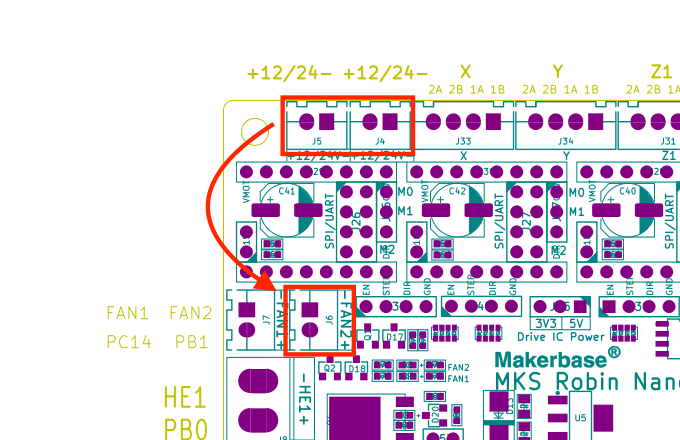

기본 배선에서, 위의 빨간 네모 둘중에 하나에 있는 히트싱크 팬 케이블을 Fan2 자리로 옮겨야 한다.

(Fan2자리로 옮기면 계속 켜져있는것이 아니라, 핫엔드 온도에 따른 조절이 가능해지게 된다)

+. 'KAMP' 가 시작과 끝 매크로에 사용되었으니 설치 바란다.

설치 방법은 아래 Github이나 유튜브 영상을 찾아보면 된다..

https://github.com/kyleisah/Klipper-Adaptive-Meshing-Purging

GitHub - kyleisah/Klipper-Adaptive-Meshing-Purging: A unique leveling solution for Klipper-enabled 3D printers!

A unique leveling solution for Klipper-enabled 3D printers! - GitHub - kyleisah/Klipper-Adaptive-Meshing-Purging: A unique leveling solution for Klipper-enabled 3D printers!

github.com

# This file contains common pin mappings for the Two Trees Sapphire

# Plus V3 (SP-5) printer (Robin Nano 3, all 2225 drivers at 32 microsteps).

# This file contains common pin mappings for MKS Robin Nano V3

# boards. To use this config, the firmware should be compiled for the

# stm32f407. When running "make menuconfig", select the 48KiB

# bootloader, and enable "USB for communication".

# The "make flash" command does not work on the MKS Robin. Instead,

# after running "make", copy the generated "out/klipper.bin" file to a

# file named "Robin_nano_v3.bin" on an SD card and then restart the

# MKS Robin with that SD card.

# See docs/Config_Reference.md for a description of parameters.

[include mainsail.cfg]

[include KAMP_Settings.cfg]

[mcu]

serial: /dev/serial/by-id/usb-Klipper_stm32f407xx_3F0020000150305148383820-if00

restart_method: command

[printer]

kinematics: corexy

max_velocity: 500

max_accel: 4500

max_z_velocity: 25

max_z_accel: 100

[virtual_sdcard]

path: /home/webcur2010/printer_data/gcodes

on_error_gcode: CANCEL_PRINT

[exclude_object]

[stepper_x]

step_pin: PE3

dir_pin: !PE2

enable_pin: !PE4

microsteps: 16

rotation_distance: 40

endstop_pin: !PA15

position_endstop: 0

position_max: 300

homing_speed: 50

[stepper_y]

step_pin: PE0

dir_pin: !PB9

enable_pin: !PE1

microsteps: 16

rotation_distance: 40

endstop_pin: !PD2

position_endstop: 300

position_max: 300

homing_speed: 50

[stepper_z]

step_pin: PB5

dir_pin: !PB4

enable_pin: !PB8

microsteps: 16

rotation_distance: 8

endstop_pin: !PC8

position_endstop: 0

position_max: 330

#Uncomment if you have a BL-Touch:

#position_min: -3

#endstop_pin: probe:z_virtual_endstop

[extruder]

step_pin: PD6

dir_pin: PD3

enable_pin: !PB3

microsteps: 16

rotation_distance: 5.6055

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: PE5

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PC1

#control: pid

#pid_Kp: 14.669

#pid_Ki: 0.572

#pid_Kd: 94.068

min_temp: 0

max_temp: 250

pressure_advance: 0

pressure_advance_smooth_time: 0.040

max_extrude_cross_section: 7

max_extrude_only_distance: 100

[filament_switch_sensor filament_sensor]

switch_pin: !PA4

runout_gcode: BEEP P=1500

#[extruder1]

#step_pin: PD15

#dir_pin: !PA1

#enable_pin: !PA3

#heater_pin: PB0

#sensor_pin: PA2

[heater_bed]

heater_pin: PA0

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PC0

min_temp: 0

max_temp: 130

#control: pid

#pid_Kp: 325.10

#pid_Ki: 63.35

#pid_Kd: 417.10

[heater_fan heater_fan]

pin: PB1 # Heatsink

[fan]

pin: PC14 # Part cooling

[bed_screws]

screw1: 35,35

screw2: 275,35

screw3: 275,275

screw4: 35,275

[display_status]

[pause_resume]

[firmware_retraction]

retract_length: 3

retract_speed: 55

unretract_extra_length: 0

unretract_speed: 55

[input_shaper]

shaper_freq_x: 50

shaper_type_x: mzv

shaper_freq_y: 50

shaper_type_y: mzv

[skew_correction]

########################################

# TMC2209 configuration

########################################

[tmc2209 stepper_x]

uart_pin: PD5

run_current: 0.800

stealthchop_threshold: 999999

[tmc2209 stepper_y]

uart_pin: PD7

run_current: 0.800

stealthchop_threshold: 999999

[tmc2209 stepper_z]

uart_pin: PD4

run_current: 1.200

stealthchop_threshold: 999999

[tmc2209 extruder]

uart_pin: PD9

run_current: 0.800

stealthchop_threshold: 999999

#[tmc2209 extruder1]

#uart_pin: PD8

#run_current: 0.800

#stealthchop_threshold: 999999

########################################

# ABL (CRtouch) configuration

########################################

#[bltouch]

#sensor_pin: #VERIFICAR #^PD2

#control_pin: #VERIFICAR #PA8

#set_output_mode: 5V

#pin_move_time: 0.4

#stow_on_each_sample: False

#probe_with_touch_mode: False

#x_offset: 43

#y_offset: 10

#z_offset: 0

#samples: 2

#sample_retract_dist: 2

#samples_result: average

#[bed_mesh]

#speed: 120

#horizontal_move_z: 5

#mesh_min: 53, 53

#mesh_max: 285, 290

#mesh_min: 46.50,0.75

#mesh_max: 253.5,295.85

#probe_count: 5,5

#algorithm: bicubic

# [safe_z_home]

# home_xy_position: 150,150

# speed: 80

# z_hop: 10

# z_hop_speed: 10

########################################

# EXP1 / EXP2 (display) pins

########################################

[board_pins]

aliases:

# EXP1 header

EXP1_1=PC5, EXP1_3=PD13, EXP1_5=PE14, EXP1_7=PD11, EXP1_9=<GND>,

EXP1_2=PE13, EXP1_4=PC6, EXP1_6=PE15, EXP1_8=PD10, EXP1_10=<5V>,

# EXP2 header

EXP2_1=PA6, EXP2_3=PE8, EXP2_5=PE11, EXP2_7=PE12, EXP2_9=<GND>,

EXP2_2=PA5, EXP2_4=PE10, EXP2_6=PA7, EXP2_8=<RST>, EXP2_10=<3.3v>

# Pins EXP2_1, EXP2_6, EXP2_2 are also MISO, MOSI, SCK of bus "ssp1"

# See the sample-lcd.cfg file for definitions of common LCD displays.

########################################

# Macros

########################################

[gcode_macro START_PRINT]

gcode:

{% set BED_TEMP = params.BED_TEMP|default(60)|float %}

{% set EXTRUDER_TEMP = params.EXTRUDER_TEMP|default(190)|float %}

# Start bed heating (but don't wait for it)

M140 S{BED_TEMP}

# Use absolute coordinates

G90

# Reset the G-Code Z offset (adjust Z offset if needed)

SET_GCODE_OFFSET Z=0.0

# Home the printer

G28

# # Move the nozzle near the bed

# G1 Z5 F3000

# # Move the hotend inside the bed

# G1 X5 Y5 F3000

# # Move the nozzle very close to the bed

# G1 Z0.2 F300

SMART_PARK

# Set nozzle heating (no waiting)

M104 S{EXTRUDER_TEMP}

# Wait for bed to reach temperature

M190 S{BED_TEMP}

# Wait for nozzle to reach temperature

M109 S{EXTRUDER_TEMP}

LINE_PURGE

[gcode_macro END_PRINT]

gcode:

# Turn off bed, extruder, and fan

M140 S0

M104 S0

M106 S0

# Move nozzle away from print while retracting

G91

G1 X-2 Y-2 E-3 F300

# Raise nozzle by 10mm

G1 Z10 F3000

G90

G1 X5 Y5

# Disable steppers

M84

#*# <---------------------- SAVE_CONFIG ---------------------->

#*# DO NOT EDIT THIS BLOCK OR BELOW. The contents are auto-generated.

#*#

#*# [heater_bed]

#*# control = pid

#*# pid_kp = 72.770

#*# pid_ki = 1.080

#*# pid_kd = 1225.264

#*#

#*# [extruder]

#*# control = pid

#*# pid_kp = 22.497

#*# pid_ki = 1.190

#*# pid_kd = 106.297'3d Printing > Klipper' 카테고리의 다른 글

| Klipper - Crowsnest를 이용한 카메라 추가 (1) | 2024.02.15 |

|---|